Vital Elements to Assess Prior To Getting an Engine for Optimum Functionality

From engine power and efficiency to fuel effectiveness and maintenance factors to consider, each factor plays an essential duty in figuring out the engine's viability for a particular application. Compatibility with existing automobile systems and available guarantee and assistance alternatives can considerably influence the lasting performance and cost-effectiveness of the engine.

Engine Power and Performance

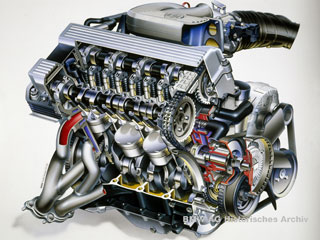

When thinking about engine power and efficiency, it is important to review the particular requirements of the planned use to guarantee optimum effectiveness and effectiveness. The power result of an engine directly affects its performance capacities, impacting factors such as velocity, pulling capability, and overall functional stamina. Understanding the needs of the application is crucial in determining the appropriate equilibrium of power and efficiency features.

Engine power is typically determined in devices such as horse power (hp) or kilowatts (kW), suggesting the quantity of job the engine can execute in time. Greater power ratings normally cause much better velocity and full throttle, making them ideal for applications requiring quick responsiveness or sturdy tasks. Nevertheless, it is essential to match the engine's power output to the certain requirements of the meant usage to stay clear of inadequacies or unneeded strain on the machinery.

In addition, engine efficiency encompasses a series of aspects past simply power, consisting of gas efficiency, discharges manage, and integrity - bmw 318ti. Evaluating these elements together with power factors to consider is crucial for guaranteeing that the engine not only provides the essential toughness yet also operates sustainably and durably in its intended environment

Fuel Efficiency and Usage

Taking into consideration the essential role of engine performance in determining its suitability for various applications, the evaluation of gas efficiency and intake ends up being extremely important in maximizing functional expenses and environmental influence. Fuel efficiency refers to the engine's capacity to convert gas into useful energy effectively.

When analyzing fuel intake, it is crucial to analyze the engine's specific metrics, such as gallons of gas consumed per hour or miles per gallon, relying on the application. Understanding just how much fuel an engine takes in under various operating conditions can aid anticipate long-term costs and plan for effective gas management approaches.

Additionally, innovations in engine innovation, such as crossbreed systems or fuel injection renovations, can significantly improve gas efficiency and minimize intake. Prioritizing engines with remarkable gas efficiency and lower intake prices can result in considerable financial savings and promote sustainability in different markets.

Compatibility With Lorry Equipments

Making sure smooth assimilation and optimal performance, the compatibility of an engine with car systems is a crucial factor to assess before making an acquisition choice. The engine acts as the heart of a vehicle, and its ability to work harmoniously with the different systems within the automobile is crucial for overall functionality.

Compatibility includes a variety discover here of elements, including electric systems, transmission systems, and exhaust systems. An engine that is not suitable with these crucial parts can bring about concerns such as electric breakdowns, ineffective power transfer, and raised exhausts.

In addition, compatibility with onboard computer system systems is essential for modern vehicles. The engine must be able to communicate effectively with the vehicle's computer to ensure correct efficiency surveillance and diagnostics.

Maintenance and Longevity Factors To Consider

Durability considerations also entail assessing the engine's style, modern technology, and compatibility with the vehicle to make sure optimal performance throughout its life expectancy - bmw 318ti. Engines i was reading this with sophisticated attributes like reliable air conditioning systems, resilient elements, and fuel-efficient styles have a tendency to have much better long life and require fewer repair work. By prioritizing maintenance and choosing an engine recognized for its longevity, customers can make an educated choice that boosts their lorry's performance and overall driving experience

Warranty and Assistance Alternatives

Given the essential role of maintenance and durability factors to consider in picking an engine, a prudent customer must currently focus on reviewing the offered warranty and assistance options. The guarantee provided with an engine can vary considerably in between makers and versions.

Assistance services can range from technical help hotlines to on-site upkeep and fixing services. A strong support system can considerably lower downtime in case of engine failure or issues, ultimately saving time and money.

Conclusion

In final thought, when acquiring an engine, it is critical to assess its power, fuel effectiveness, compatibility with lorry systems, maintenance requirements, longevity, and guarantee choices. These crucial aspects play a considerable role in identifying the optimal functionality of the engine. By thoroughly thinking about these elements, buyers can ensure that they are buying an engine that fulfills their demands and provides reputable performance over time.

From engine power and efficiency to sustain effectiveness and maintenance considerations, each variable plays a crucial function in identifying the engine's suitability for a particular application.Engine power is typically measured in units such as horsepower (hp) or kilowatts (kW), suggesting the amount of work the engine can execute over time.Thinking about the vital function of engine performance in establishing its suitability for numerous applications, the analysis of gas effectiveness this website and usage becomes extremely important in maximizing operational expenses and ecological impact. Fuel effectiveness refers to the engine's capability to convert gas right into usable power efficiently. In addition, thinking about the quality of products and construction of the engine is vital as it can directly affect toughness and how well the engine stands up to wear and tear over time.